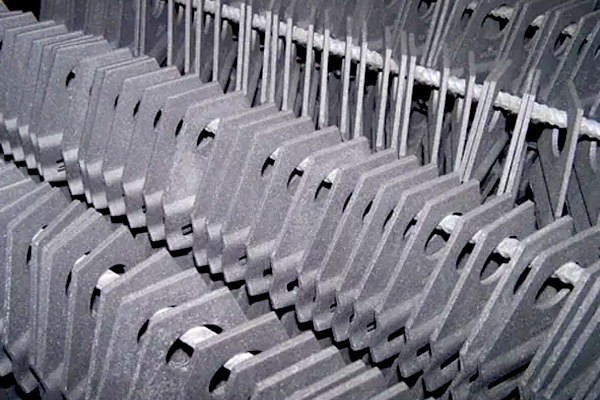

Zinc Phosphating

Zinc phosphating is a surface treatment process that creates a protective layer of zinc phosphate on metal substrates, primarily steel and iron. This treatment is widely used to enhance corrosion resistance, improve adhesion for paints and coatings, and provide a surface conducive to lubricants.

Key Benefits:

Corrosion Resistance: The zinc phosphate layer acts as a barrier, protecting the metal beneath from rust and corrosion, particularly in humid or aggressive environments.

Improved Adhesion: The textured surface created by the phosphating process enhances the adhesion of paints, sealants, and other coatings, improving their performance and longevity.

Lubrication: The porous nature of the zinc phosphate coating allows it to retain lubricants, which can reduce friction and wear in moving parts.

Aesthetic Appeal: The finish typically has a matte gray appearance, which can be visually appealing for certain applications.