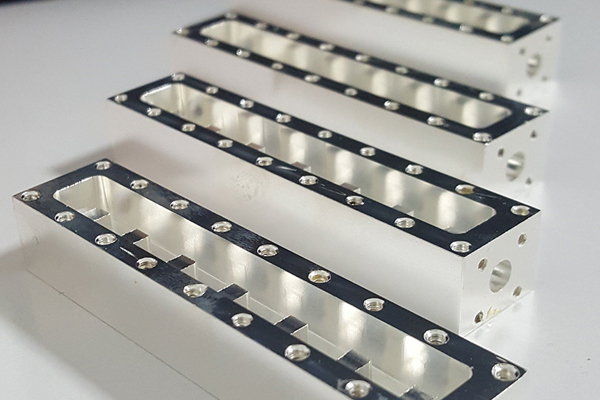

Silver Plating

Allied Industries offers a wide range of silver plating services including matte, semi-bright and bright silver deposits. Purities up to 99.9% pure are available with Type I, matte, 99.9% pure silver plating services available for wire bonding or defense applications. Our company has the ability to underplate with various nickel plating services including both bright electrolytic nickel, sulfamate electrolytic nickel and electroless nickel deposits as well as copper plating if required.

Inhibiting of silver plating services with RoHS compliant post plate chromates and triazoles are available. In addition, nitrogen backfilled, and sealed packaging is available to eliminate the potential for tarnishing of uninhibited deposits. Nitrogen bagging can extend the shelf life of silver plated products indefinitely ensuring low contact resistance and solderability at time of assembly when the packaging is opened.

Silver Plating Services – Silver Deposit Properties

Silver is an extremely ductile metal with a brilliant white luster. It has the highest electrical and thermal conductivity of all metals as well as the highest optical reflectivity in the visible range (gold plating is superior in the infrared range). Silver offers excellent high-temperature lubricity making it an excellent coating for anti-galling and anti-seizing applications on high temperature nuts and bearing surfaces with service temperatures up to 1200F. 99.9% pure, matte silver offers excellent solderability and wire bonding ideal for lead frames and circuit applications.

Silver has been known since ancient times for making jewelry and high-end utensils and is generally considered a precious metal. In reality silver is more properly designated a semi-precious metal due to the fact that it readily tarnishes, forming silver sulfide on the surface when exposed to air or water containing an oxidant and source of sulfur.

Nickel Plating Services – Advanced Plating Technologies’ Capabilities

Specifications:

AMS 2410 (Less High Temp Bake)

AMS 2411

AMS 2412

ASTM B700: Type 1, 2, & 3

QQ-S-365: Type 1, 2, & 3

Most Company Specifications

Purity:

99.9% (Matte Only)

99.00%

98.00%

Finish Type:

Matte Deposits

Semi-Bright Deposits

Bright Deposits (Mechanical)

Underplates Provided:

Bright Electrolytic Nickel

Sulfamate Electrolytic Nickel

Electroless Nickel (High or Medium Phosphorous)

Copper

Tin, Lead or Tin/Lead

Heat Treatments:

Hydrogen Embrittlement Bakes

High Temperature Bakes up to 750F

Methods:

Selective Loose Piece Plating

Sheet Product (Chemically Milled/Etched Sheets)

Segmented Strips (Frets)

Barrel

Rack

Wire

Vibratory