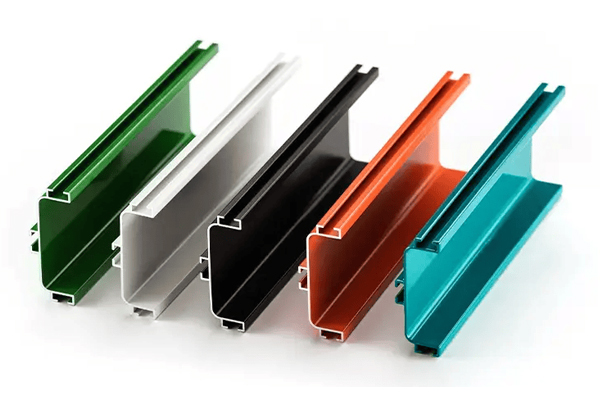

Anodized Coating

In the literal meaning, anodised coating refers to the electrolytic oxidation of aluminium. Anodic oxidation or anodisation are other names for this process. This coating is intended to improve aluminum's resistance to corrosion while also giving it a more attractive appearance. The application's scope must be taken into consideration while choosing a coating type. Anodised coatings' light fastness and paint adherence are adjusted based on client requirements.

Chromic Acid Anodizing

It has excellent paint adhesion performance despite its thin surface coating and great corrosion resistance and surface flaws. Because of these advantages, it is primarily chosen in the aerospace sector. The thickness of the coating ranges from 0.5 to 17 µm.

Sulphuric Acid Anodizing

Mostly utilised in locations that require ornamental elements and excellent corrosion protection. The thickness of the coating ranges from 1.7 to 25 µm.

Hard Anodizing

It is employed in situations requiring high coating thickness, corrosion resistance, and resistance to wear and friction. The thickness of the coating ranges from 12.5 to 110 µm.