Automobile

Manufacturers in the auto industry continuously seek solutions to protect their products from the potential damage caused by wear and corrosion. Because vehicle components face exposure to contaminants like salt, sand, dirt, animal droppings and acid rain, the parts underneath a vehicle and below the hood are susceptible to corrosion. Without protective measures, rust can spread quickly and eventually destroy these valuable components, leaving the vehicle inoperable.

Allied Industries Plating Company specializes in surface finishing and metal electroplating services for automotive parts across various applications in the automotive industry. Besides offering industry-best corrosion resistance, our plating services provide metal finishes that increase hardness and durability while enhancing a part’s overall appearance. We have delivered high-performance plating solutions to automakers for decades, including the operation of multiple rack and barrel systems for the Big 3 Automotive and Tier 1 suppliers.

Corrosion Resistance : Corrosion Protection is the most significant advantage that metal plating and surface finishing provide. These plating processes enable vehicles to stay on the road longer by reducing the maintenance and repair costs associated with rust and corrosion.

Wear Resistance : Applying the optimal plating to critical automotive components increases hardness and limits the impact of wear and tear, resulting in extended life spans. Longer intervals between repairs and replacements lead to increased cost savings and lower consumer ownership costs.

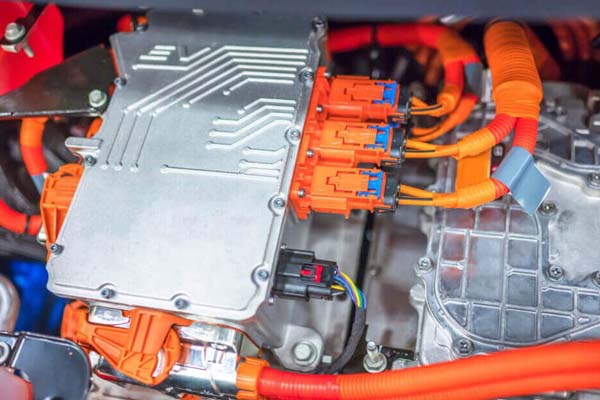

Conductivity : Nickel coating processes with low phosphorus content work well for improving conductivity in electronic components while increasing bonding capabilities and maximizing resistance to alkali solutions.

Improved Adhesion : Improved Adhesion In processes like electroless plating, some coatings enhance the adhesion of overlying plated metals or secondary protective coatings.

Enhanced Appearance : Many surface finishing processes add smoothness, luster and shine to automotive components, increasing the aesthetic appeal and overall product appearance.

Zinc Plating

Zinc and nickel form an alloy that's one of the most effective solutions against corrosion and offers superior performance in elevated temperatures, plus exceptional abrasion and scratch resistance. These coatings often combine with passivation layers to provide increased protection.

Zinc-nickel plating

Electroless nickel-phosphorus plating delivers excellent lubricity, superior hardness and uniform thicknesses, making it an ideal protective solution for wear and corrosion. These surface treatments work well for auto parts like pistons, heat sinks, engine bearings, hose couplings, exhaust systems and other engine components.

OEM Automotive Plant

Original equipment manufacturer (OEM) coatings protect a vehicle's exterior surface while enhancing its aesthetic appearance. These coatings can be solvent- or water-based, offering excellent protection in harsh environments and extreme temperatures.

OEM Automotive Plant

Thread sealants lock and seal threaded fittings to resist leakage and the effects of vibration, moisture, engine fluids and fuel. These sealants stand up to high temperatures while offering superior lubrication that promotes easy assembly and disassembly.

Theard Sealing And Locking

Thread sealants lock and seal threaded fittings to resist leakage and the effects of vibration, moisture, engine fluids and fuel. These sealants stand up to high temperatures while offering superior lubrication that promotes easy assembly and disassembly.

Custom Coating Development

Our engineers enjoy tackling the surface challenges of unique applications. We have extensive experience developing customized coatings and processes to serve your specialized needs